Cable recycling means the separation of metal and insulation - not an easy task in large scales. Motivated, competent employees and the most modern technology are at work around the clock to achieve this.

Welcome to Zirec

Processing begins with the exact registration and weighing of the material lots delivered.

The material delivered is first unloaded, then expertly classified and sorted.

Suitable cable is processed in the slitting department, where metal cores are ‘peeled’ out of the plastic insulation.

The greater part of the cable material, however, first undergoes preliminary milling in the coarse grinder …

…and is placed in small containers for further processing.

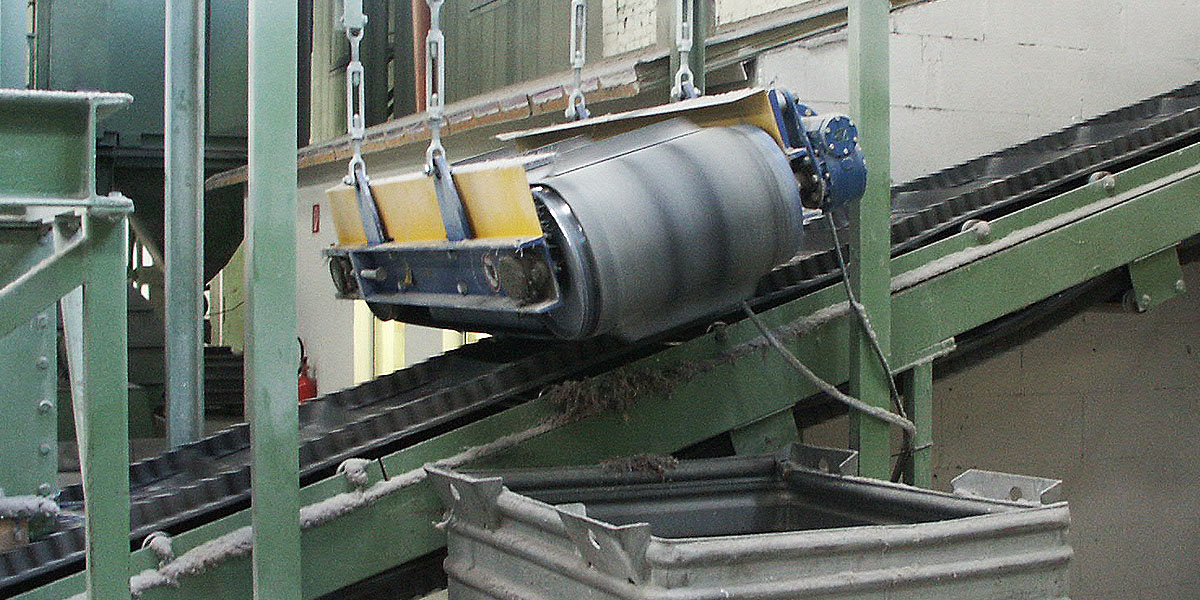

The milled cable is transported from the filling area via a belt conveyor with magnetic separator to the fine grinders.

Here the cable material is milled down to the required filter size in several steps, in which more magnetic separators are used.

At the separating table the separation of metal and plastic is carried out using a ”setting and vibration” process.

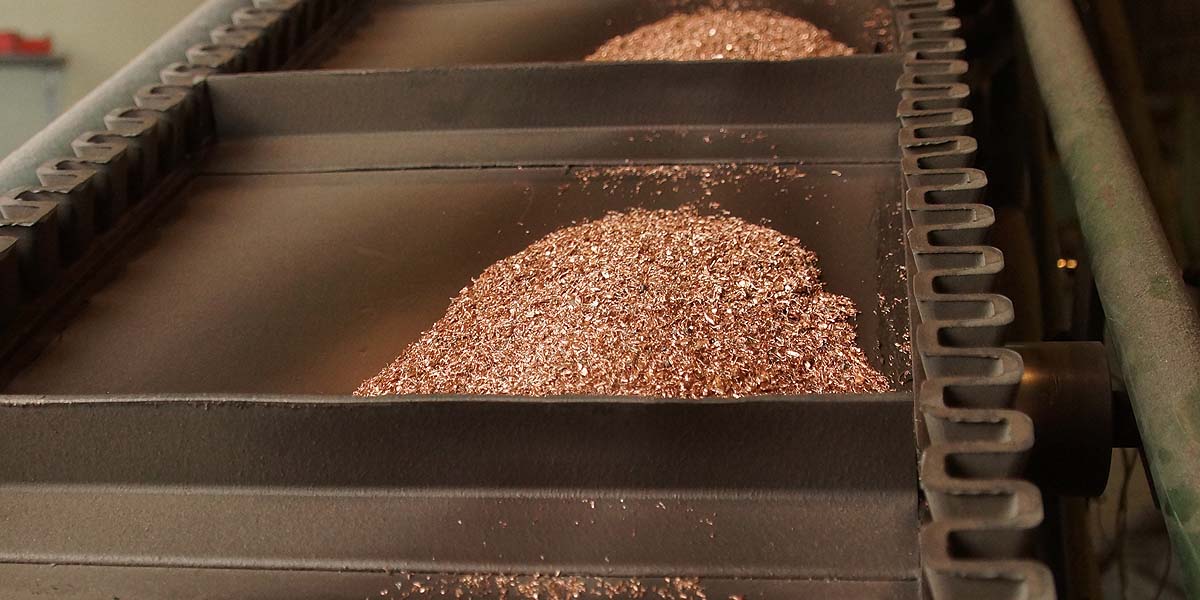

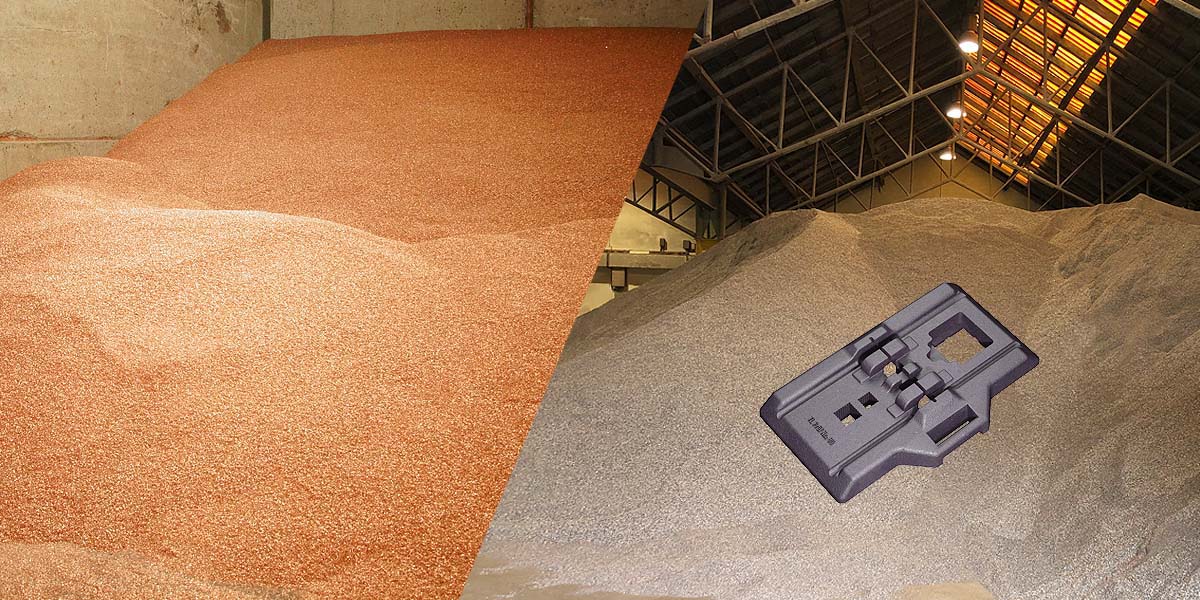

The result is high-quality metal granulates in precisely specified qualities.

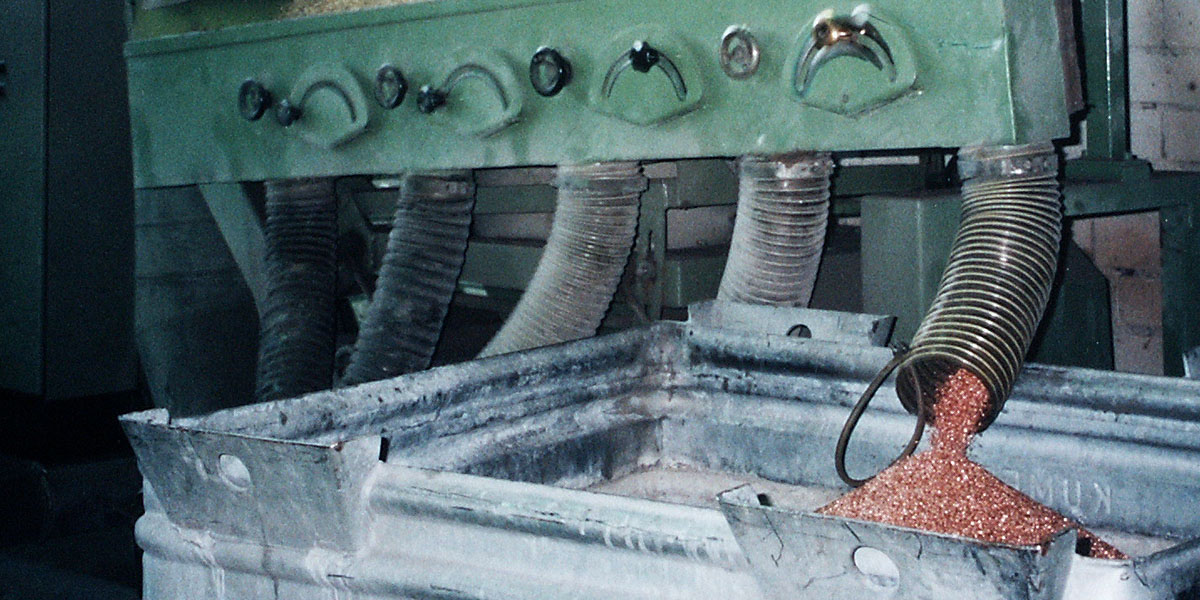

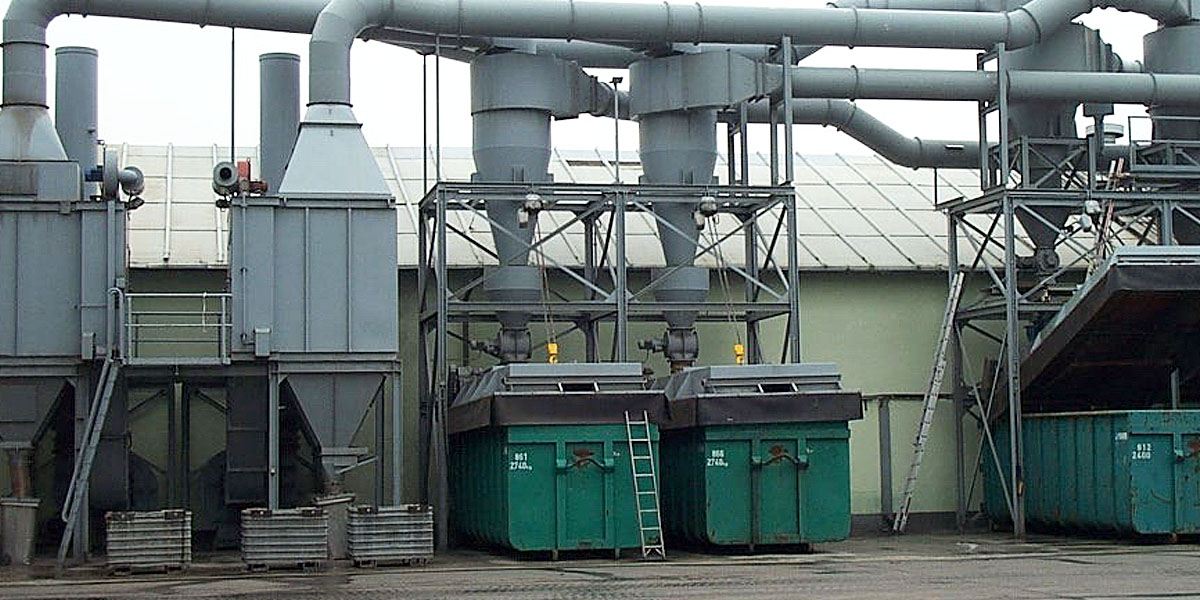

By means of blowers and filters the remaining metal is removed from the plastic.

With the help of special filters the various plastic fractions can be cleanly separated.

The metal granulates are sorted by quality and then collected in special boxes, while the plastics are put into the plastics storage.

According to customer requirements the batches are compiled, weighed ...

…and loaded and registered under strict controls in the container yard.

The secured containers are taken over by our own vehicles and forwarding agents around the clock to be delivered to our customers.